Rifletuner

AH Members-

Posts

825 -

Joined

-

Last visited

-

Days Won

73

Content Type

Profiles

Forums

Events

Shop

Everything posted by Rifletuner

-

Thanks guys 👍

-

Thanks guys. I appreciate the comments 👍

-

Just finished up a knife with my first go at using sambar antlers for the handle. A guy that I used to hunt with does a bit of forging and wanted to learn about knife making after seeing some of my knives. He spent a few days with me last year, and I took him through the whole process. He offered to give me some antler for handle material, and I was happy to take him up on the offer. As expected, I learned a few things in the process of working with the antler, but pretty happy with how this first one turned out. Steel is 2.5mm VG10 stainless random pattern Damascus in a full flat grind. The handle is a tapered tang with antler scales, black G10 liners and brass pins & lanyard tube.

- 11 replies

-

- 13

-

-

Thanks mate 👍 Hey, Im always happy to share pics of my boner 🤣🤣🤣 Thanks mate 👍 AEBL is a stainless steel that I would class "razorblade steel". There are a number of steels including AEBL, 12C27, SF100 and others that are commonly used for making knives, that started life as a steel produced for the big razor companies. AEBL is a great steel for knife making because it has a good combination of corrosion resistance, strength and edge retention. You can get better performing steels, but you need to pay double or more for the steel. So AEBL hits a sweet spot for me. Thanks mate 👍 Thanks mate 👍

-

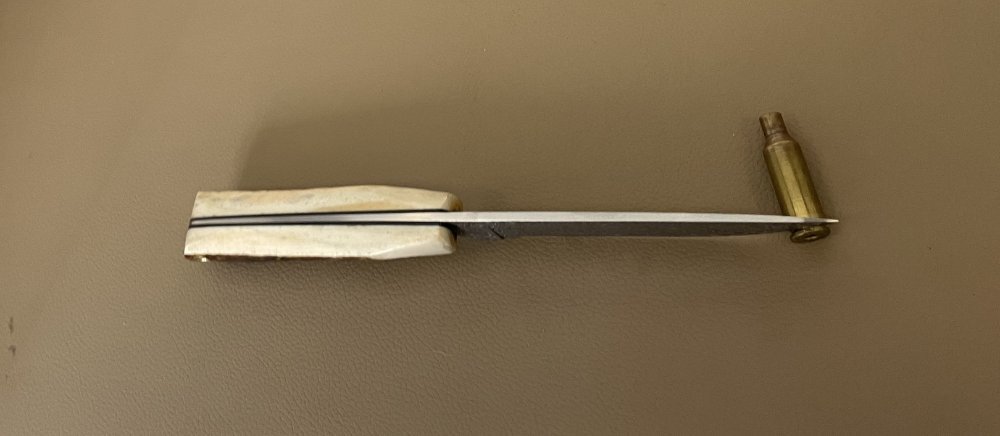

Just finished another of my boner design over the weekend and pretty happy with how it came out. Steel is 2.5mm AEBL stainless. Bevel is a hollow grind with a very thin, slicey edge. Handles are mallee burl with orange resin from Artisan Supplies, orange G10 liners and G10 pins and a hand rubbed Aussie oil finish.

- 8 replies

-

- 12

-

-

Thanks 👍 I actually like seeing them go to other people. I have gotten a lot of photos back from people using my knives and thats really what I enjoy the most. I make them to be used, so seeing people happy after they used one of my knives is great. Thanks mate 👍

-

Thanks mate 👍 I dont actually do the leather work myself, but the guy who makes them does excellent work.

-

A few months ago after going to the Melbourne knife show, I decided I was going to get a table at Australia's biggest knife show in Sydney. In the lead up to the show, I was madly trying to finish knives that I wanted to bring with me. I fully intended to photograph all the knives I made before I left for the show. But of course I worked late into Thursday night, then left home at 0715 Friday morning to drive 10 hours up to Sydney. So I really only just got a chance to start photographing what I made now that I am back home. This is a hunter pattern I have made for a few years. The steel is 3mm NitroV, with cryo treatment after the heat treat. The hardness on this is 61-62 Rockwell. The blade is a full flat grind down to .2mm at the edge. The tang tapers to about 1mm. The handle material is gidgee, with 1mm red G10 liners and copper Loveless bolts. The handle has a hand rubbed oil finish. I also made a near identical model with stainless Loveless bolts, but that one sold at the show. It had better figure in the handle material, so pretty sure that is why the guy went for that particular knife. The last photo is off my table at the show just after I set up Saturday morning.

-

Hi mate. Its a totally manual process. I use either https://nordicedge.com.au/uncle-bjorns-handle-finish-australia-only/ or https://ausmakersupplies.com.au/products/u-beaut-aussie-oil-250ml Its just me and an old bit of soft T-shirt material. Put a couple of drops on the rag and rub it in for about 2 minutes. Leave it for 10-20 minutes, then do it again. Repeat 10 to 15 times and you are done. Its similar to a "London Best" gun stock oil finish, just a bit quicker.

-

Thanks mate 👍

-

Yeah, it will be brittle. Try putting it in an oven for 2 hours at around 150C, let it cool to room temperature, then give it another 2 hours in the oven. Ideally you want to do that right after its cooled from the quench, but you could still give it a go. This is the down side of using mystery steels though, as the quench and temper is all guess work. If you use a known steel like 1075, there is a pretty specific heat treatment to follow for the best results.

-

Hey, nice. Did you temper after the quench?

-

No worries. If you have any questions, just ask. There is any number of Youtube videos that cover this. Thats how I spent a lot of my early time learning, and still pick up little details now.

-

Thanks mate 👍

-

Hi mate. If you look in the knife sub forum, you will see a few of my knife builds. The whole subject of knife steel is a long and complicated one. To begin with, I will keep it as simple as I can. Most often, people recommend starting with high carbon steels like 1075, 1085 or 1095 because they are fairly easy to work with and the most forgiving to heat treat. If you look here: https://ausmakersupplies.com.au/products/1075-high-carbon-steel you can buy a small piece pretty cost-effectively. I see he only has 3mm in stock at the moment, but that is a really good size for most outdoor / hunting knives. The guy that runs Aus Maker Supplies also offers heat treating of knives, so you have the option to make a knife and send it to him to heat treat. The big variable in all this is how you make a knife start to finish. You CAN use a file on carbon steel for everything UP TO heat treat stage. But you need to leave the blade edge at at least 1mm thickness to prevent a warp during heat treat. And once its heat treated, a file is not going to touch it. You can use something like an angle grinder with a flapper disk to finish the edge post heat treat - just take it slow and dont overheat it or you will ruin the HT on the knife. I started off with basic gear, but I have always used a professional heat treating service to do my heat treat for me. They use a kiln that pumps all the oxygen out of the furnace and fills it with inert gas which significantly reduces warping. But the best process I have found is to profile out the knife shape and drill any holes, get it heat treated without grinding the bevels, then grind the bevels after heat treat. I have not had any warping since I started doing that, but it means you are grinding and hand sanding a fully hardened blade, so you really need a belt grinder for that.

-

Thanks mate 👍 Its great to see it in action. That was my first ever knife from Magnacut steel. Thanks mate 👍

-

Its part of point 20 "You should be able to answers specific questions regarding how and where the blade was heat-treated. And if done in shop, what procedures and equipment were used". A lot of people heat treat their own, but I get mine done by a heat treat shop local to me. I would like to do my own, but I need to sell a few more knives to afford the $6000 to $9000 for a heat treat oven. Thanks mate

-

The assessment covers all aspects of the knife. Take a look at this checklist: https://akg.org.au/wp-content/uploads/2022/06/FULL-DOC-Assessment-Checklist-for-Guild-Membership.pdf It gives a full breakdown of what the assessor looks at. Plus it saves me typing a detailed answer 🤣🤣🤣 I dont know what the scores usually look like. I actually didnt think to ask. I really thought I would be getting 10 to maybe 15 for each knife, so was pleasantly surprised. Full membership will take me a while I think. I already have an idea of the knives I want to build for that test, but I need a mill for that step. I think probably it will be a couple of years before I am at that stage. But its funny how you progress over time. I have been making knives since 2016, but it was really the lockdowns from 2020 that got me spending a lot of time making knives. So the last 4 years has been the bulk of the time I have been at it. And when I look back at the knives I have made, the serious development has been in the last 2 years. Hopefully I will be able to get out and do a few training sessions with good knife makers to focus on the things I need to do for the full member assessment.

-

Thanks mate. I appreciate it 👍

-

For the last 18 months I have been working towards becoming a member of the Australian Knifemakers Guild. The Guild has two categories of knife makers, a Probationary Member and a Full Member. There is a third category Life Member if selected & voted for by the membership, but there are only a handful of these. At a high level, you can think of it in terms of a Probationary Member being an entry level knife maker, and a full member is an advanced knife maker. Thats not a perfect description, but its near enough. To advance to these levels, there is a formal checklist of requirements (see here if interested https://akg.org.au/wp-content/uploads/2022/06/FULL-DOC-Assessment-Checklist-for-Guild-Membership.pdf). To get to Probationary membership, you need to present 3 knives for assessment and achieve a mark of 10 out of 20 for each knife. Once you are a Probationary Member, you can sit for Full Member a minimum of 12 months later and need to achieve a minimum of 18 out of 20 for each of the 3 knives, but there are also specific things you need on the assessment knives that are not required for the probationary test. I have been working for a while to get 3 knives to have assessed, but I keep on picking some fault and deciding its not at the standard required. Occasionally I have a really fantastic knife finished that I am super happy with, but its promised to someone with a very close deadline, so I cant hang onto it until I have the other knives I need to make up the set of three for assessment. Anyhow, I finally booked a date to go see Adam Parker, one of 2 Guild assessors in Vic, and a guy with over 30 years of knife making experience. Adam is between Geelong and Ballarat, and with the traffic on Wednesday, it took me 3 hours each way to go see him. I had a couple of knives that I recently finished, plus I was planning to use a kitchen knife I just finished a day before the appointment. But I found a few scratches on the blade that I wasn't happy with, so at the last minute I took a survival knife I finished a few months ago to make up the required knives. At the end of the assessment process, I ended up scoring 16 out of 20 for the survival knife, 18 out of 20 for the bushcrafter, and 20 out of 20 for the hunter. So as of Wednesday, I am a Probationary Member of the Australian Knifemakers Guild

- 21 replies

-

- 11

-

-

-

Thanks mate. Appreciate the feedback. Hey, mate, thanks I really do appreciate your comments. I am mostly self taught, and I enjoy trying to get better. I post my knives on a couple of forums as it has been a helpful way to find what people like or dislike in the different designs I have tried. I do take peoples feedback on board, and it is one of the things that has helped me improve over the years I have been doing it. I enjoy making them, but my main goal is to keep improving.