Leaderboard

Popular Content

Showing content with the highest reputation since 08/07/24 in Posts

-

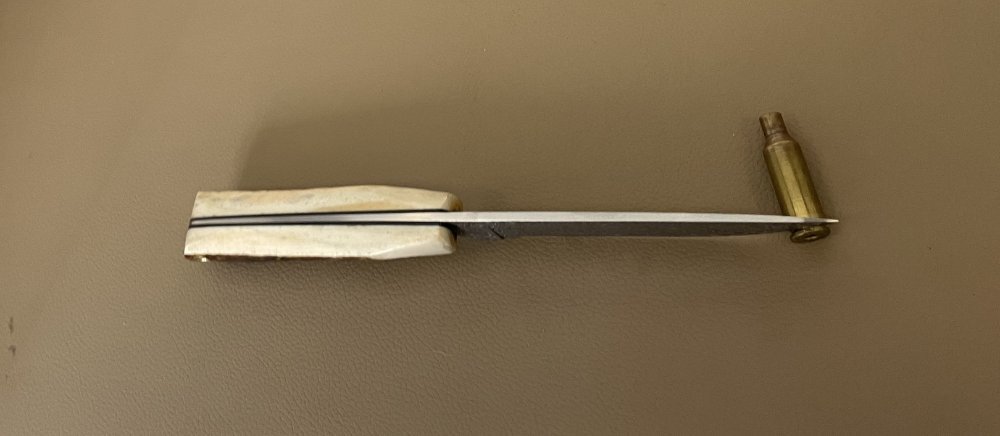

Just finished up a knife with my first go at using sambar antlers for the handle. A guy that I used to hunt with does a bit of forging and wanted to learn about knife making after seeing some of my knives. He spent a few days with me last year, and I took him through the whole process. He offered to give me some antler for handle material, and I was happy to take him up on the offer. As expected, I learned a few things in the process of working with the antler, but pretty happy with how this first one turned out. Steel is 2.5mm VG10 stainless random pattern Damascus in a full flat grind. The handle is a tapered tang with antler scales, black G10 liners and brass pins & lanyard tube.13 points

-

12 points

-

Just finished another of my boner design over the weekend and pretty happy with how it came out. Steel is 2.5mm AEBL stainless. Bevel is a hollow grind with a very thin, slicey edge. Handles are mallee burl with orange resin from Artisan Supplies, orange G10 liners and G10 pins and a hand rubbed Aussie oil finish.12 points

-

A few months ago after going to the Melbourne knife show, I decided I was going to get a table at Australia's biggest knife show in Sydney. In the lead up to the show, I was madly trying to finish knives that I wanted to bring with me. I fully intended to photograph all the knives I made before I left for the show. But of course I worked late into Thursday night, then left home at 0715 Friday morning to drive 10 hours up to Sydney. So I really only just got a chance to start photographing what I made now that I am back home. This is a hunter pattern I have made for a few years. The steel is 3mm NitroV, with cryo treatment after the heat treat. The hardness on this is 61-62 Rockwell. The blade is a full flat grind down to .2mm at the edge. The tang tapers to about 1mm. The handle material is gidgee, with 1mm red G10 liners and copper Loveless bolts. The handle has a hand rubbed oil finish. I also made a near identical model with stainless Loveless bolts, but that one sold at the show. It had better figure in the handle material, so pretty sure that is why the guy went for that particular knife. The last photo is off my table at the show just after I set up Saturday morning.8 points

-

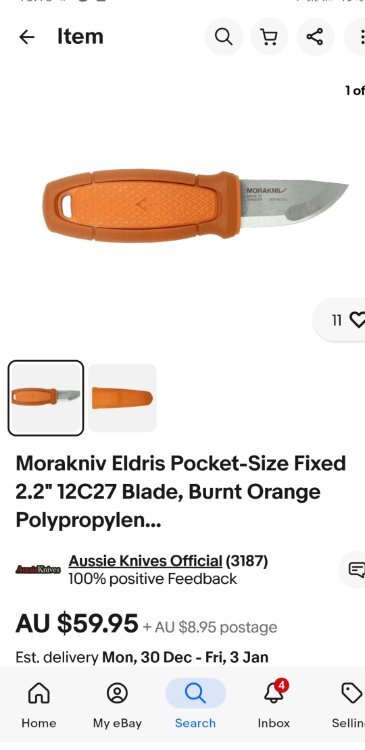

Bought this knife from ebay for shits and giggles. cut up 5 sambar and still sharp to do maybe 2 more, then the first sharpen. I'm finding it very useful for the back legs, maybe the best knife I've used to cut them out. Back straps, it works on them but have used better performing knives. The blade is a tad small Yes it gets a laugh when it comes out to cut up the sambar6 points

-

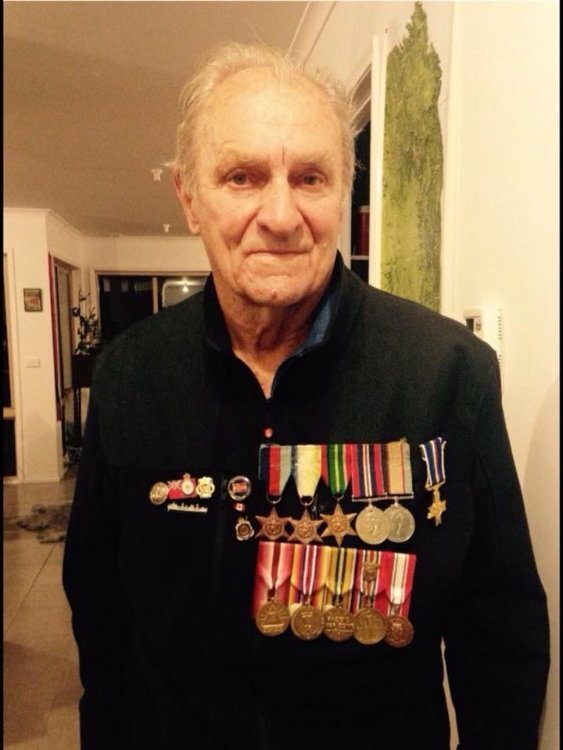

With out a doubt the greatest Sambar hunter to walk the hills. I was very lucky and blessed to have known him and spent funny times in the bush with him. when I was in my late 20's we would back pack into Dan area and would always find all this dog food, sleeping bags and pots and pans you name it, all stashed in logs. One time sitting in camp I could see coming down the ridgeline this wolf. Now we did have a little bit of alcohol in camp but not much as its all weight when back backing, so I new I wasn't pissed. Next thing I could see pink paint and pink ribbons on the dog. The dog came right up to us and just sat down. This was Fang as Piranha was just getting too old. We looked at each other and thought WTF. Then this old guy came down the hill with his combo rifle/ shotgun, old shitty pack he got from the Op shop and hunting attire from the same shop. Who needs Kuiu gear 🤣. He then notice the old guy with us and it was like 2 school kids yacking away for hrs. That trip turned into a full on educational tip and probable the best one I've been on. Over the years as Hank got older we would take him away a lot more and was more about taking the piss out of each other with a little bit of hunting put in. Hank was the toughest guy I have met. He told me one time he new there was a nice stag up this gully, so he just slept overnight under a tree with his poncho on in the rain. Next morning he got up and shot the stag. No Instagram or Facebook to get likes in those days🤣 He stories of his life is truly amazing and fascinating. Life of adventures. From working on the ships in the merchant navy to logging in Canada and in the query's blowing shit up. He story's of at sea are unbelievable. One ship he was on got hit by a torpedo and he was stuck in the water tied up too a fellow ship mate. Taking in turns to sleep, Hank woke up and his mate looked asleep. Hank pushed him to have a go at him for sleeping and he began bobbing in the water. A shark came up and ripped off the bottom half of his ship mate. When your number is up, its up. There a many, many, many stories about Hank and his adventures. We wanted a book to be written about him but he always said I don't remember dates. I remember years ago we would go to Western port ADA meetings. It was more a night out for us than been at the meeting. Now no one would ever really talk to us but that didn't worry us at all. But this one trip we asked Hank if he wanted to come. Now Hank pretty much kept to himself in his latter years but he agreed. Well we had a few old guys come up to use and we had the great KP started talking to us. Anyhow the next meeting, Hank didn't come but we became the flavor of the month. But one thing I will remember was KP said to us that we all follow in his footsteps in the bush. I have heaps of cool stories and that's just me. I find it so sad that hardly anyone knows of him and the new modem Sambar hunter would not last a day with him in the bush. No Maps, No GPS nothing but his brain. The man was a Gps and would remember everything. Parks changed laws because of him and his dogs. They could never find him when they went looking for him. Was funny as he didn't need any mod cons and would go a few days with out food but would always have food for the dogs.5 points

-

4 points

-

4 points

-

3 points

-

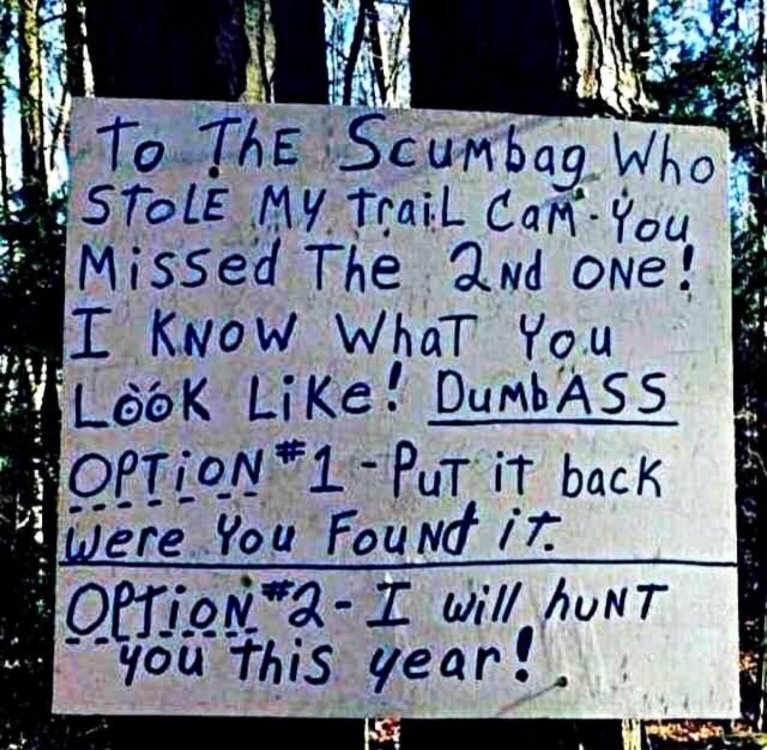

Fill up the cards with other pictures ....goatse, tubgirl, good holesome stuff. Alternatively. a virus.3 points

-

3 points

-

3 points

-

3 points

-

I just had a phone call regarding this subject, it is a difficult one to give a full answer to. So I have made a page on my web site Australian night vision, down on the facts about thermal page to try to explain my thoughts on this subject. I stand by to be proven wrong though. 😊3 points

-

A report rom 2010 below. Rob Fickling loaned me a pack when he first started making them,as below it served me really well...well enough to order my own for the next years trip. Got into Victoria yesterday and just home this morning from packing the Moroka30 75L pack around the hills for ten days with Shankspony and Lost and Late,two Kiwi boys that would walk the legs off any bastard. May 12 ,flew into Christchurch on the East coast then we drove six hours across the NZ Alps to the West Coast to Fox Glacier and propped there overnight for the trip in the next morning. We set out in pouring rain for our first camp which was a non stop 6.5 hour trip through rough as shit country. The rain didnt stop.We stayed there two days and the second arvo 1.5 clicks upstream from camp and a click off the river I rolled two Chamois bucks one evening for our tucker and then next day we walked another 11 k`s up river which resulted in us three hunters being 28 k`s off the road from where the truck was parked. We traveled through rivers,creeks, bush,####n jungle,avalanche chutes,under glaciers that were dropping ice chunks the size of farm sheds and through boulder fields and it was all the way up hill to where the big bull Tahr were way to ery above us.This was no walk in the park down a gravel road trip this was pain all the way but through the most incredible country I have ever seen. Shankspony had a 300 metre long avalanche of ice and snow roar down the chute he was on and it stopped 200 m`s above him, he had been glassing Chamois across the valley when he heard it coming and as he said "i got the #### out of there quick as " I saw the avalanche trail myself and the 1/2 k plumes of snow and ice dust hanging in the air from another that rumbled down from a glacier above us...geezuz! It was tough on the gear and on the feet, three of my toenails will drop off this or next week and believe me the knees and hips are feeling it too. I have walked through a million frosts but have never climbed through rocks where they are covered in black ice,you cant see it but it was coating every bloody thing you put a boot on,some places were hands on all the way and a slip could have had horrible consequences. Having done an Achilles several years ago i was pretty wary of putting my feet down correctly. Robs Moroka 30 gear? Undoubtedly as good as it gets,tough well and truly made properly and i loved especially the rifle carrier in the middle of the pack as an outstanding extra...climbing through the bush and the rocks meant a hunter had both hands to hang on with and that was a definite bonus. The pack stood up to everything thrown at it and coped with it all,rain,falls,rocks and scrub and with a total weigh up of just over 30 kilos it proved its worth.. with its inherent toughness,comfort and a multitude of pockets for everything i have concluded that its worth recommending to anyone that wants to pack in to anywhere. "haha thats if my recko is worth anything" The Moroka 30 s/bag was too hot for me and i used it as a blanket unzipped, heaps of room and warmth galore,my mate was in a feather bag and calling the temps 'cold' through the night even though he was tightly zipped up,i was warm as! Great bag with a monster amount of room too.3 points

.thumb.jpg.850983bd195f5e386d8997888b94c418.jpg)