Leaderboard

Popular Content

Showing content with the highest reputation since 07/03/10 in all areas

-

Just finished up a knife with my first go at using sambar antlers for the handle. A guy that I used to hunt with does a bit of forging and wanted to learn about knife making after seeing some of my knives. He spent a few days with me last year, and I took him through the whole process. He offered to give me some antler for handle material, and I was happy to take him up on the offer. As expected, I learned a few things in the process of working with the antler, but pretty happy with how this first one turned out. Steel is 2.5mm VG10 stainless random pattern Damascus in a full flat grind. The handle is a tapered tang with antler scales, black G10 liners and brass pins & lanyard tube.13 points

-

13 points

-

13 points

-

12 points

-

Just finished another of my boner design over the weekend and pretty happy with how it came out. Steel is 2.5mm AEBL stainless. Bevel is a hollow grind with a very thin, slicey edge. Handles are mallee burl with orange resin from Artisan Supplies, orange G10 liners and G10 pins and a hand rubbed Aussie oil finish.12 points

-

For the last 18 months I have been working towards becoming a member of the Australian Knifemakers Guild. The Guild has two categories of knife makers, a Probationary Member and a Full Member. There is a third category Life Member if selected & voted for by the membership, but there are only a handful of these. At a high level, you can think of it in terms of a Probationary Member being an entry level knife maker, and a full member is an advanced knife maker. Thats not a perfect description, but its near enough. To advance to these levels, there is a formal checklist of requirements (see here if interested https://akg.org.au/wp-content/uploads/2022/06/FULL-DOC-Assessment-Checklist-for-Guild-Membership.pdf). To get to Probationary membership, you need to present 3 knives for assessment and achieve a mark of 10 out of 20 for each knife. Once you are a Probationary Member, you can sit for Full Member a minimum of 12 months later and need to achieve a minimum of 18 out of 20 for each of the 3 knives, but there are also specific things you need on the assessment knives that are not required for the probationary test. I have been working for a while to get 3 knives to have assessed, but I keep on picking some fault and deciding its not at the standard required. Occasionally I have a really fantastic knife finished that I am super happy with, but its promised to someone with a very close deadline, so I cant hang onto it until I have the other knives I need to make up the set of three for assessment. Anyhow, I finally booked a date to go see Adam Parker, one of 2 Guild assessors in Vic, and a guy with over 30 years of knife making experience. Adam is between Geelong and Ballarat, and with the traffic on Wednesday, it took me 3 hours each way to go see him. I had a couple of knives that I recently finished, plus I was planning to use a kitchen knife I just finished a day before the appointment. But I found a few scratches on the blade that I wasn't happy with, so at the last minute I took a survival knife I finished a few months ago to make up the required knives. At the end of the assessment process, I ended up scoring 16 out of 20 for the survival knife, 18 out of 20 for the bushcrafter, and 20 out of 20 for the hunter. So as of Wednesday, I am a Probationary Member of the Australian Knifemakers Guild11 points

-

Last time I visited AH member Gryphon, he showed me a box of wood he had salvaged and had been meticulously drying the pieces out over the years. Gryphon kindly gave me several pieces of his stash to use for putting handles on my knives builds. When I got home, I decided to make Gryphon a knife and handle it with some of his wood. I picked out a piece of sheoak, and wanted the rest of the knife to match the quality of the handle material. Historically knife steels can have good edge retention, good strength or good abrasion resistance. But knife steel hasnt had all three of these criteria in one steel. So the knife maker has to decide which characteristic they are prepared to compromise on when they choose a steel to make a knife. Magnacut is a relatively new stainless "super steel" which was made specifically for knife making. It is formulated to balance out the three desirable characteristic of edge retention, strength and corrosion resistance, and has proven to be vary popular with knife makers since it was released a couple of years ago. When the first shipment of Magnacut arrived in Australia at the end of last year, I immediately bought some, and though it was a fitting steel to pair with the Sheoke handle material. The knife I made for Gryphon is the first knife I have ever made from Magnacut. The blade of this knife is a full flat grind in 3mm steel. The design pf the knife is my version of the Bark River Gunny Hunter. Once I shaped the handle, I found the grain in this block of wood is really stunning. I added red G10 liners, brass Corby bolts and a brass lanyard tube. I gave the handles a hand rubbed oil finish, and it really set to wood off I think. I wanted something special for the sheath too. I sent the knife a friend in Queensland as I am not set up for leather working yet. I got him to add a sambar motif to the sheath and really think the sheath sets off the knife well. I was able to drop off the finished knife to its new owner last weekend, so looking forward to hearing about it being put to use on the deer.11 points

-

I thought I would add in pictures of knife builds as I finish them since there was a lot of interest in the last one I posted. This one is a mini version of a larger Bowie design that I have made in the past. This version should be a good allrounder. Steel is 3mm NitroV with a full flat grind, with a distal taper to the point. Handle material is black Ritchlite with green G10 liners & pins.11 points

-

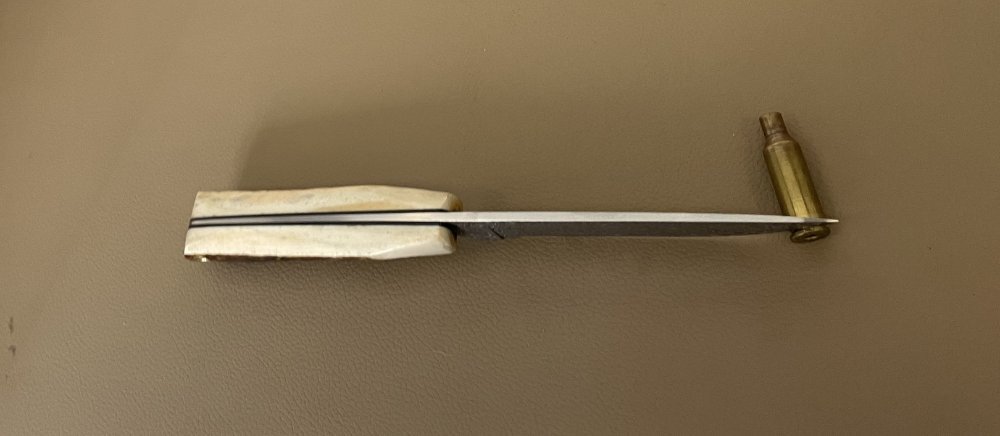

Hello all. I give this bloke in town a bit of venison from time to time. I also give him a few fallow casts as I know he mucks around making a few knifes. Last week he turns up at home with this gift. A skinning knife design made out of one of my casts and a concrete cutting blade. Hopefully I'll try it out in a few weekends. Brett11 points

-

Here's a few pics of my latest knife. The blade is 440c with stabilised birdseye redgum & a black/white/black spacer, stainless & brass mosaic pins and a stainless lanyard hole. The push-fit sheath is actually brown but the crappy little camera doesn't like photographing leather properly. The handle is a bit slimmer than usual as it has been made to fit a female hunter's hand. Even though redgum is a dense wood, it 's grain is a little more open than some other Aussie hardwoods, hence you can see the light reflecting off some of the open grain. It can be filled but I like to keep as much of the original texture of the wood a possible.11 points

-

Another variation on a knife I have made a few times now. I am going to have to come up with a name because I think I will be making a few more soon. Second time working with Chinesium VG10 Damascus steel. This was a 3mm billet, and the layers are slightly off centre which is a bit of a pain. Guess I cant really expect quality control from Chinese production. Luckily it has enough core steel to sharpen up with a good edge. Last time I etched Damascus, I left it a bit too long and it etched pretty deep. This time I etched it for much shorter periods. Its probably a little under done this time. I will maybe split the difference next time. The blade is a full flat grind with a tapered tang. Handle is African ebony with thin red G10 liners, mosaic pins and a hand rubbed oil finish.10 points

-

Late last year I made my first chefs knife & gave it to my step mother for Christmas. This year I decided to make chefs knives for my two brothers and sisters in law. I asked each of them for their favourite colours, so ended up with blue and pink for one couple, and orange and green for the other couple. I like making these knives, but phuk is there some grinding to get them done. I start by getting the the profiled blade in 4mm AEB-L heat treated. To get a nice lively & functional blade, I start off grinding a full flat bevel which also gives the blade a distal taper, then grind in a hollow for the "S" grind which lightens up the blade some more and helps with food release, then taper the tang to balance out the blade. I probably grind away 50% of the steel, though I keep forgetting to weigh one before and after grinding. Then with their colour preferences I had to work out the best way to incorporate the colours into the handles. I had a piece of stabilised maple with blue and pink die through it that I used for one, though unfortunately a lot of the pink in the wood ended up getting ground out of it during the shaping of the handle. I added pink liners, and really wanted to use pink pins as well, but no one in Australia sells them. I could have got them overseas, but left my run too late form them to arrive in time. For the other handle, I made a segmented handle by cutting & joining orange and green G10 on a fine black liner, then glued them up with contrasting orange & green G10 pins. The whole process took me a lot longer than I expected and I was a bit worried I wouldnt get them done in time. But I finished them yesterday, and will give them out at a family dinner tonight.10 points

-

If you dont know the story of Harry Wolhuter and his "lion killer" knife, its definitely worth a read: https://southafrica.co.za/legend-of-harry-wolhuter.html The knife itself was made by Thomas Williams Butchers Cutler in London and was from a pattern commonly used for slaughtering sheep in the 1800s. I used the template produced by Pops Knife Supply: https://popsknife.supplies/pages/lion-killer to make my knife. The blade is 3mm SF100 stainless, with a full flat grind and a tapered tang. The handle is gidgee scales with thin red G10 liners, brass pins & a brass mosaic lanyard tube. Handle finish is hand rubbed Aussie oil.9 points

-

Hi I was so fortunate recently to be given a new knife for a significant birthday. It was made by Rob Podesta from Ulladulla (0437 389 251). I would never have contemplated buying myself such as knife but as a gift I am amazed how good it looks and how good it feels. It has a buck eye burl for the handle and a nice Damascus blade. I had to ring Rob to thank him personally. He was great in providing some tips on how to look after it. He also said to make sure to use it. It annoys him when people buy his knives and then don't use them because they are so nice.9 points